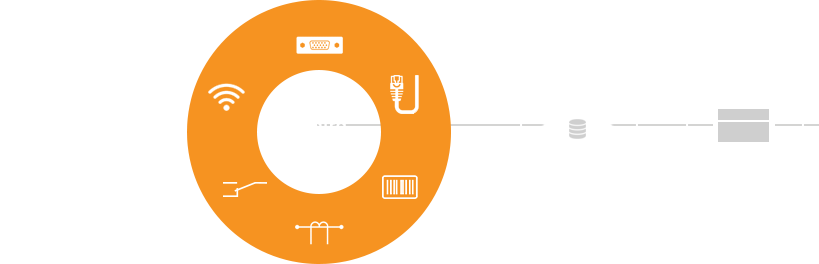

Machine

Monitoring System

Real-time production and condition monitoringMachine status (On/ Off/ Idle) and utilizationMachine downtime tracking and analysis of its associated root causesMachine Cycle time, Cutting time, Run time, Stop time and Idle timeOEE software solution proactively measures machine effectivenessNumber of parts produced/ Rejected/ ReworkedMeasure of production output from each cell of the shop floorSpindle speed and feedServo and spindle motor temperaturePulse coder temperature